Intimate service comes from the recognition of customers, and proposes high-quality product matching solutions according to customer needs

Product quality comes from rigorous and perfect quality control, and every step is full of our strict sense of responsibility

Exclusive customization comes from personalized configuration solutions, timely and efficient supporting new product development and production

Fast distribution originates from sufficient inventory + processing + fast logistics, and upholds enthusiastic and efficient management

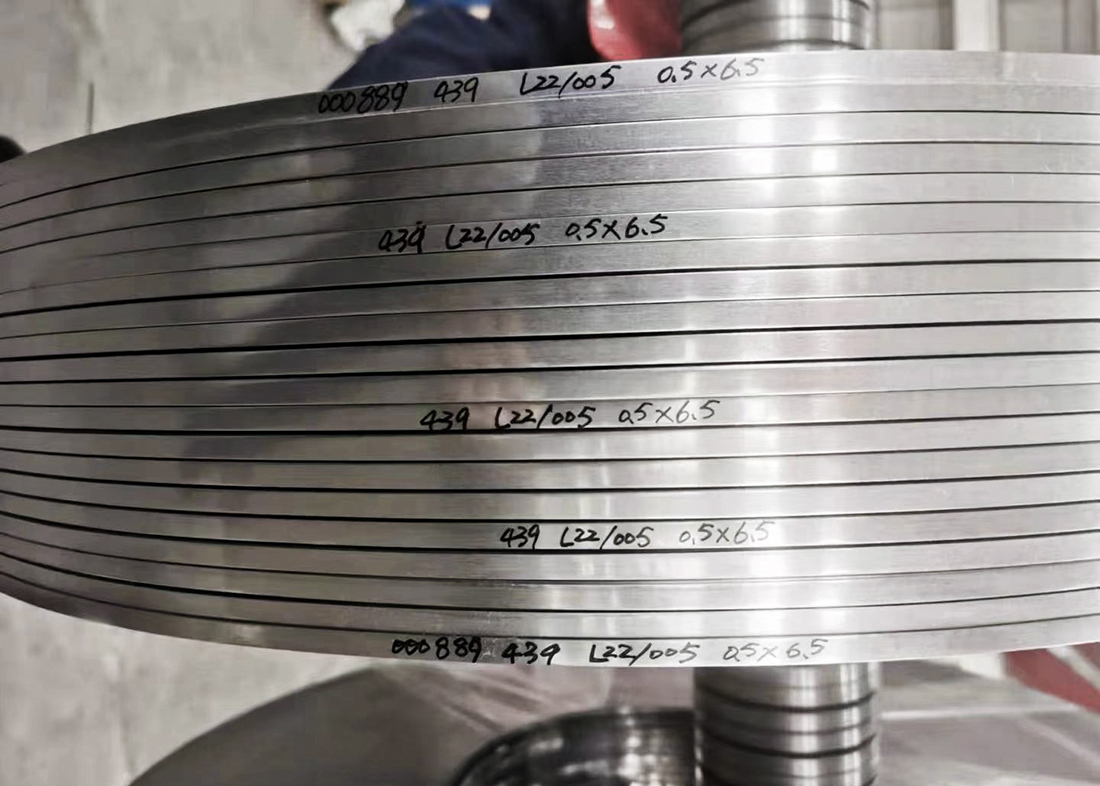

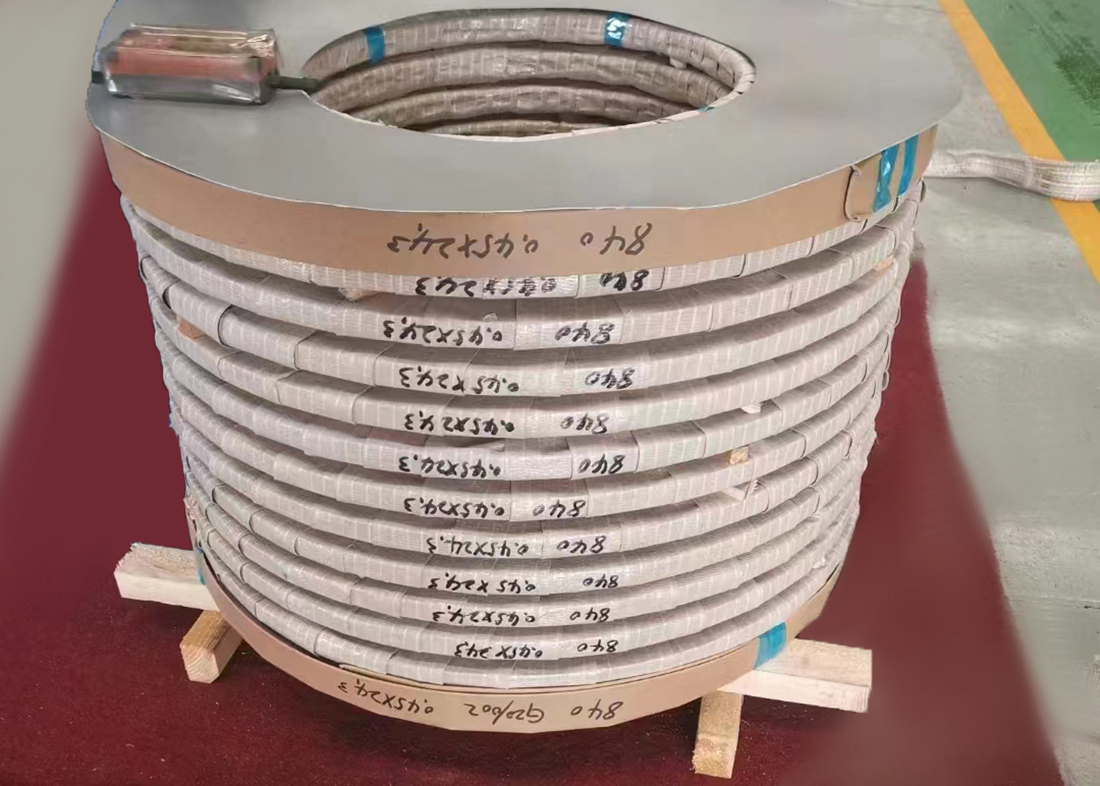

From raw material detection to warehousing registration management, to ensure the overall quality of products

From surface treatment to standard comparison

From material cutting and processing control to re-inspection, packaging and delivery

Every step is full of our strict sense of responsibility

Special material stainless steel is mainly produced with a thickness of 0.02mm-3.1mm and a width of 1mm-1500mm

Relying on the company's domestic and foreign processing equipment and logistics network throughout the country

From customer orders to fit stock screening

Then to processing, production, re-inspection and distribution

Our R&D team has established good cooperative relations with domestic and foreign steel mills

Timely and efficient cooperation with customers for product development

Combined with a Japanese-funded continuous electroplating factory, we have successfully launched gold-plated, silver-plated, nickel-plated and other electroplating products.

Products have broad market prospects and development potential

Stainless steel coils have a wide range of applications in the pharmaceutical industry, mainly including the following aspects: 1.Pharmaceutical Equipment Reactors: Used in the processes of drug synthesis, stirring, and reaction. Reactors made of stainless steel coils have good corrosion resistance and can withstand the erosion of various chemical substances, ensuring the stability and safe

The use of stainless steel belt in rail transit is mainly based on its advantages in corrosion resistance, high strength, good processing performance, fire resistance and beautiful appearance. The following is a detailed introduction: 1. corrosion resistance: the operation environment of rail transit is complex, and vehicles may face a variety of corrosion factors such as humidity, salt spray, ch

The cold rolling process of stainless steel coils is a further rolling process of hot-rolled stainless steel coils at room temperature, aimed at obtaining thinner thickness, higher surface quality, and better performance. Here is a detailed introduction: 1. Process flow Raw material preparation: Select hot-rolled stainless steel coils as cold rolling raw materials. Hot rolled coils need t

The sanding treatment of stainless steel coil is a processing technology to form uniform sanding texture on the surface of stainless steel coil by mechanical grinding or abrasive spraying. The following is a detailed introduction to the sanding treatment of stainless steel coils: 1. processing method Manual sanding: sanding stainless steel coils with workers' hand-held grinding tools requi

Stainless steel strip usually has the following performance in low temperature environment: 1. mechanical properties: as the temperature decreases, the strength and hardness will be improved. This is because the low temperature prevents the dislocation movement, which increases the difficulty of material deformation and strength. At the same time, the stainless steel strip can still maintain good

Stainless steel coils are used in marine equipment mainly because stainless steel has the advantages of corrosion resistance, high strength, good processing performance and hygiene, which can meet the requirements of ships in complex marine environment. Details are as follows: 1. strong corrosion resistance: the ship has been sailing in the marine environment for a long time, and the sea water is

Stainless steel coils have a wide range of applications in the pharmaceutical industry, mainly including the following aspects: 1.Pharmaceutical Equipment Reactors: Used in the processes of drug synthesis, stirring, and reaction. Reactors made of stainless steel coils have good corrosion resistance and can withstand the erosion of various chemical substances, ensuring the stability and safe

The use of stainless steel belt in rail transit is mainly based on its advantages in corrosion resistance, high strength, good processing performance, fire resistance and beautiful appearance. The following is a detailed introduction: 1. corrosion resistance: the operation environment of rail transit is complex, and vehicles may face a variety of corrosion factors such as humidity, salt spray, ch

The cold rolling process of stainless steel coils is a further rolling process of hot-rolled stainless steel coils at room temperature, aimed at obtaining thinner thickness, higher surface quality, and better performance. Here is a detailed introduction: 1. Process flow Raw material preparation: Select hot-rolled stainless steel coils as cold rolling raw materials. Hot rolled coils need t

The sanding treatment of stainless steel coil is a processing technology to form uniform sanding texture on the surface of stainless steel coil by mechanical grinding or abrasive spraying. The following is a detailed introduction to the sanding treatment of stainless steel coils: 1. processing method Manual sanding: sanding stainless steel coils with workers' hand-held grinding tools requi

Stainless steel strip usually has the following performance in low temperature environment: 1. mechanical properties: as the temperature decreases, the strength and hardness will be improved. This is because the low temperature prevents the dislocation movement, which increases the difficulty of material deformation and strength. At the same time, the stainless steel strip can still maintain good

Stainless steel coils are used in marine equipment mainly because stainless steel has the advantages of corrosion resistance, high strength, good processing performance and hygiene, which can meet the requirements of ships in complex marine environment. Details are as follows: 1. strong corrosion resistance: the ship has been sailing in the marine environment for a long time, and the sea water is

WeChat ID:www.webreda.com

WeChat ID:www.webreda.com